The Greatest Guide To Manufacturers

There are three extra Do D-led institutes currently in the competitors procedure. Choosing Additive Manufacturing as its first technology focus area, in Might 2012, the Do D, through a complete and open competitors, granted the National Ingredient Production Development Institute, now call America Makes. Due to the success of this initial pilot institute, the vision for the Production U.S.A. has increased significantly.

The DOE is leading two of the 5 established institutes, and is in the competitors process for one additional subject. Although really similar in nature to Do D institutes, the DOE institutes have a concentrate on tidy energy. AFFOA is working to allow a manufacturing-based revolution by transforming standard fibers, yarns, and materials into highly sophisticated, integrated and networked devices and systems.

America Makes is a nationwide accelerator and the nation's leading collaborative partner for innovation research study, discovery, creation, and development in additive production and 3D printing. The ARM Institute's objective is to develop and after that release robotic technology by integrating the varied collection of market practices and institutional knowledge across many disciplines-- sensing unit innovations, end-effector advancement, software application and expert system, materials science, human and maker behavior modeling, and quality control-- to realize the pledges of a robust manufacturing innovation community.

Smart Production works to spur advances in clever sensing units and digital process controls that can drastically improve the effectiveness of U.S. advanced production. IACMI is dedicated to accelerating development and adoption of cutting-edge manufacturing technologies for affordable, energy-efficient production of innovative polymer composites for cars, wind turbines, and compressed gas storage.

Next Flex takes essential steps towards furthering U.S. development and adoption of the flexible hybrid electronics that will reinvent the method we live, work and play. Power America is accelerating the adoption of innovative semiconductor components made with silicon carbide and gallium nitride into a large range of products and systems.

The REMADE Institute concentrates on driving down the cost of innovations necessary to recycle, recycle and remanufacture materials such as metals, fibers, polymers and electronic waste.

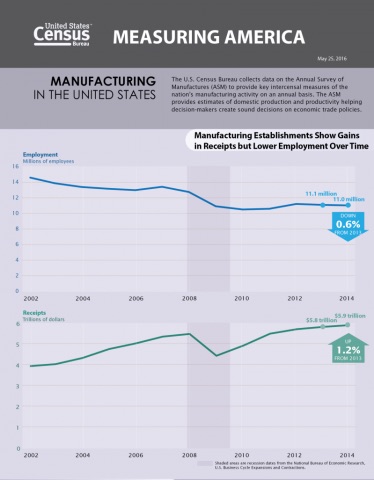

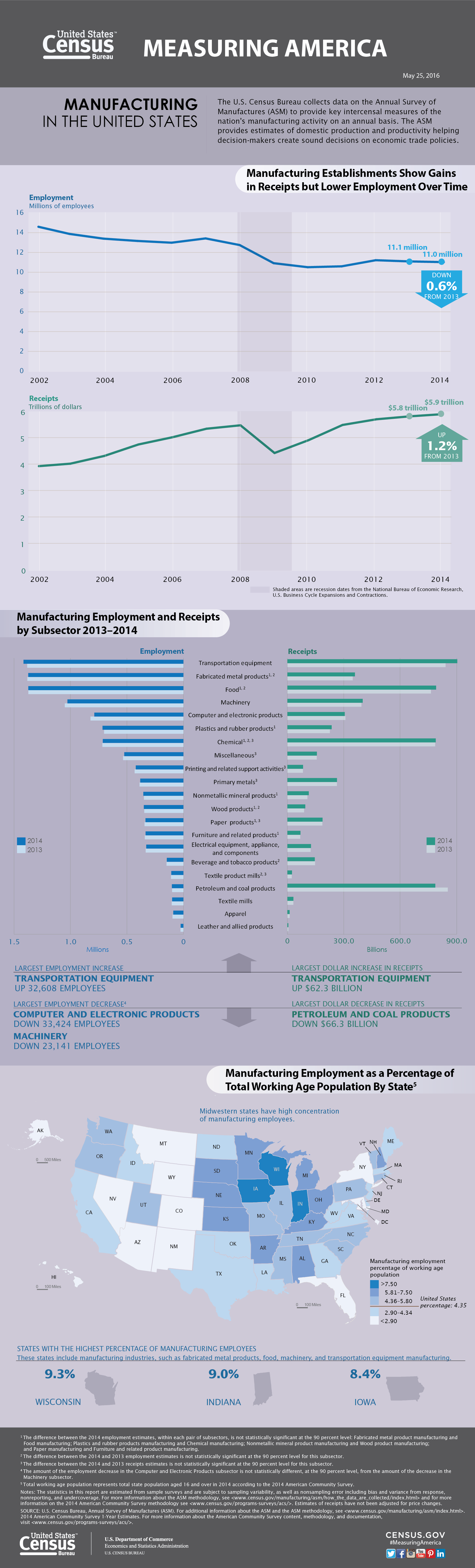

Production in the U.S. has frequently been assumed to be in long-term decline, with the competitive advantage relocating to inexpensive countries such as Mexico and China. Nevertheless, with advanced technologies most likely to automate as much as 60% of factory tasks, in the future affordable countries may no longer delight in a competitive benefit, and the U.S.

Still, the U.S. needs to be more aggressive in establishing and embracing robotic innovations, according to Justin Rose, a partner and handling director in the Boston Consulting Group's Chicago office. "If we want to stay a manufacturing powerhouse, I really see this as the only option. And the U.S. requires to lead here.

Manufacturers Things To Know Before You Buy

In a conversation with Knowledge@Wharton, Rose, who leads the operations and digital customers practice for BCG's commercial clients globally, talks about the future of U.S. production and other associated issues. An edited records of the discussion follows. Knowledge@Wharton: Could we start by speaking about your own background? How did you get interested in American manufacturing and its future? Justin Rose: Maturing, I was constantly thinking about big problems like geopolitics, energy, environment and so on.

I was blown away at the complexity and sophistication of manufacturing properties. A great deal of individuals believe about producing as hard, unclean labor-- however what I saw was complex, advanced operations. And I recognized that for many things in the world that I wanted to occur, items needed to be made to enable it.

Knowledge@Wharton: The standard view is that manufacturing in the U.S. has been in long-lasting decline, which competitive advantage in this industry has moved to nations like Mexico and China. Do you think that perspective is still valid or is it out of date, and why? Rose: It is both valid and outdated.

It is obsoleted in the sense that the U.S. still has an incredibly flourishing production sector with more than $4 trillion in annual output. In aggregate, we produce the huge bulk of what we consume in the country. What's altered in the U.S. is that our focus now is different.

While that shift has been painful in numerous parts of the nation, it is not necessarily a bad thing. We just require to make sure that we support our employees so they can continue to support their households and neighborhoods. Knowledge@Wharton: Given that you take a look at what is occurring in producing from a worldwide lens, how have altering cost structures modified the map of global manufacturing? Rose: For the last thirty years, individuals have discussed the globalization of supply chains.

There are three main reasons. First, costs are night out internationally. In 2004, in say, China, they were about 15% cheaper usually from a production expense standpoint than the United States. The average wage for a production labor was less than a dollar an hour. There weren't any safety or ecological standards to mention.

Now China is only about 5% cheaper, which does not include the additional cost of shipping products throughout the Pacific to U.S. customers. Second, there are clearly trade tensions, and deliberate reordering from "open market" to something that we refer to as managed trade. So, you see things like Brexit having an effect, the Trans-Pacific Collaboration, USMCA [United States-- Mexico-Canada Arrangement], and so on.

And most likely most fascinating is the positive point of view, and that is everything about technology. Market 4.0 or advanced manufacturing is mostly a set of technologies that permit labor to get removed from manufacturing processes. So, if a nation, and let's utilize China again, has labor that is 50% more affordable, and an item where 20% of the cost is labor, that means it would have a 10% cost benefit in general.